Capabilities

Precision Contract Manufacturing

An AS9100 & ISO9001 Registered Company

What We do

Full-Service Contract Manufacturing

Our Modern CNC machines range from Matsuura MAM 72 32-pallet 5-axis machining cells with pick-and-place robots, to Mori-Seiki and Okuma Machining Centers.

100%

Quality Inspection

75%

Reduction in Lead Time with In-House Processes

Matsuura

DMG MORI

Okuma

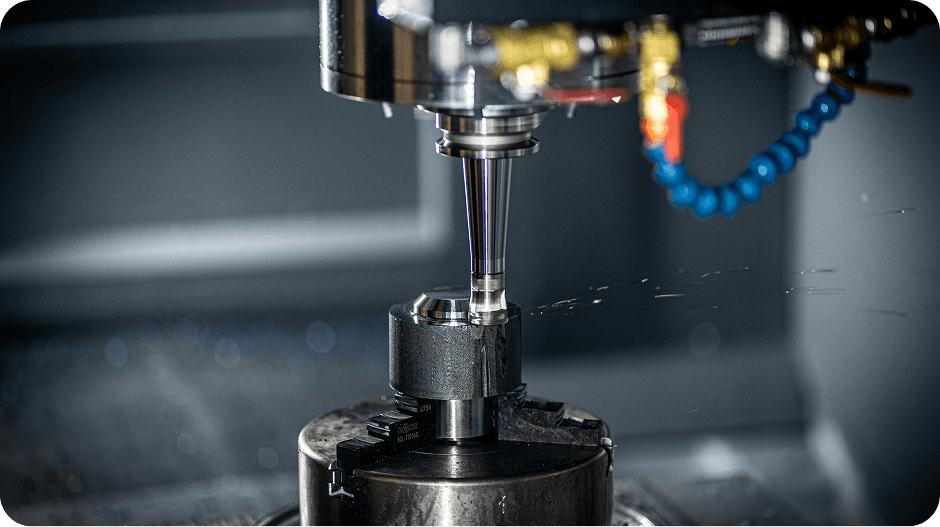

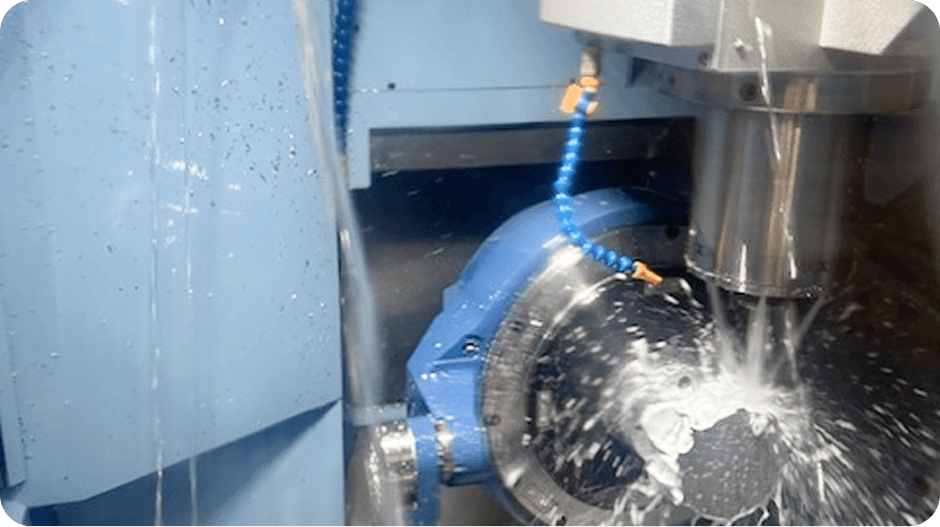

MACHINING CAPABILITIES

Advanced Machining & Manufacturing Excellence

OMW Corporation has decades of experience in all aspects of production and prototype CNC machining and assembly. We specialize in 2 through full 5 axis CNC milling and turning of small to mid-sized parts and assemblies, including complex 3D surface machining. We work with all materials, including aluminum alloys, titanium, stainless steels and hard metals, and engineering plastics. We are known for manufacturing the most complex, high tolerance parts in the world. We operate 7 days a week, 24 hours a day, 365 days a year.

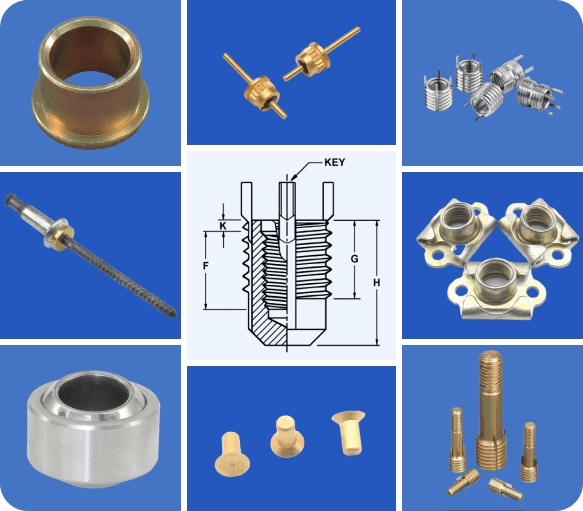

Contact Usassembly CAPABILITIES

OMW Assembly Services & Installation

OMW offers top-tier assembly services and bearing installation, featuring 5,000 sq. ft. of dedicated assembly space with the flexibility to expand as needed. With a focus on exceptional quality and ample capacity for a wide range of aerospace adhesives and primers, OMW continuously seeks to enhance our assembly capabilities. Currently, we provide the following assembly services:

Keyed Inserts

Helical Thread Inserts

Pin Installation

Riveting

Nutplates

Stud Installation

Bushing Installation

Mechanical Assembly

PEM Fastener Installation

DC Feed Installation

Bearing installation

Integration

AI-Powered & More...

OMW has partnered with state-of-the-art software partners, to integrate AI and the latest software advances into our automated production scheduling, purchasing, finance, and quoting systems. With the support of our partners, we have enhanced our manufacturing capabilities by dynamically adjusting production schedules and support areas in real time as new orders are received and priorities change. This marks the introduction of truly connected systems for modern production.